If you love the warmth and depth of real wood but need the color control, scale, and repeatability that large projects demand, LithoWood™ is made for you. It’s a paper-backed real wood veneer sheet that’s enhanced with digitally printed rare wood patterns—so you get the authenticity of wood plus the precision of modern imaging.

What exactly is LithoWood?

LithoWood starts with sustainably certified wood veneer substrates. Onto this real wood surface, Herzog Veneers prints high-fidelity images of coveted figures—think Macassar ebony ribbons, burls, birds‑eye, and bleached crotch effects—using UV‑resistant inks. The result is a consistent, repeatable face that reads as wood because it is wood, yet offers visual control previously associated with laminates.

Why designers and fabricators choose LithoWood

1) Consistency at scale (without going faux)

Repeated, dialed‑in imagery across dozens—or hundreds—of panels lets you carry the exact tone and grain from a reception desk to walls, doors, and casework. Because each face begins as real wood, the result retains the credibility and tactile presence of wood while remaining precisely controllable.

2) Access to rare looks—responsibly

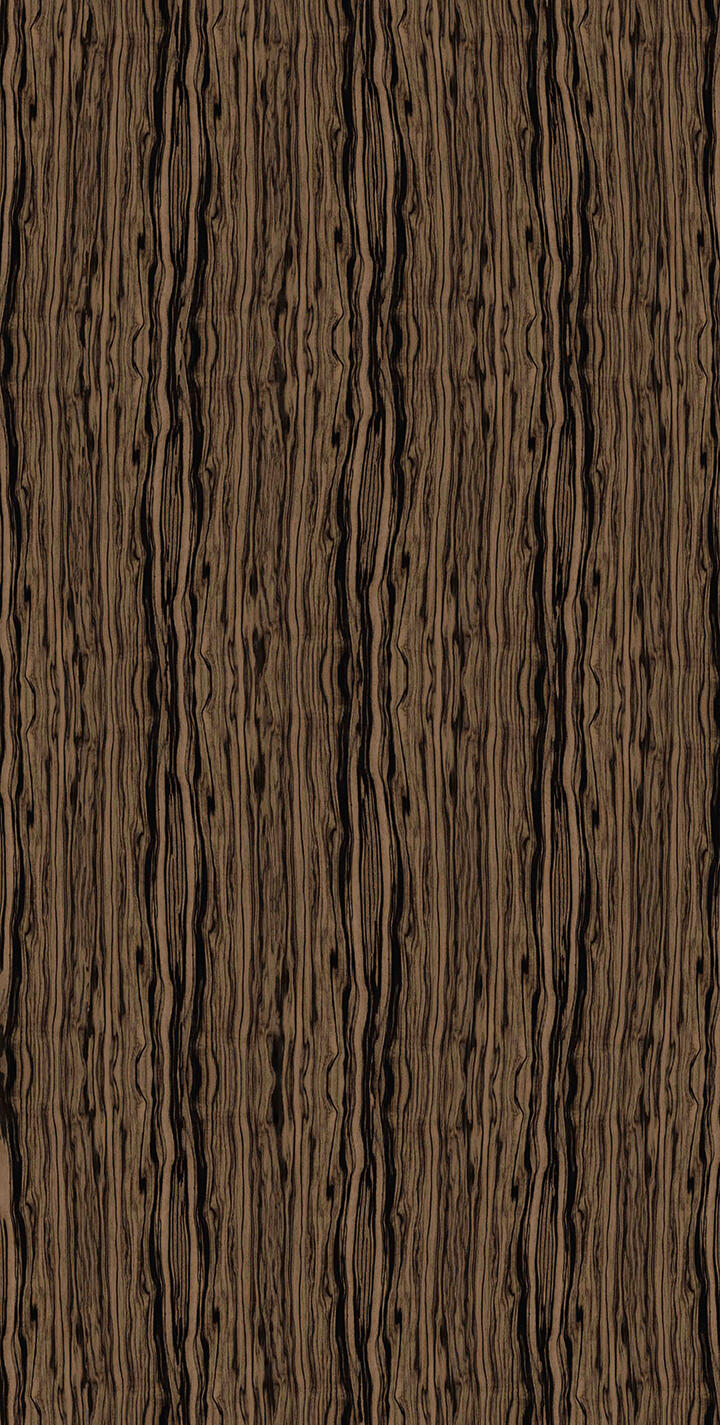

Achieve the vibe of Santos rosewood, Macassar ebony, figured mahogany, or Mozambique without hunting for a unicorn flitch. LithoWood reproduces these figures on real wood veneer substrates at accessible cost and lead times.

3) A modern palette for modern spaces

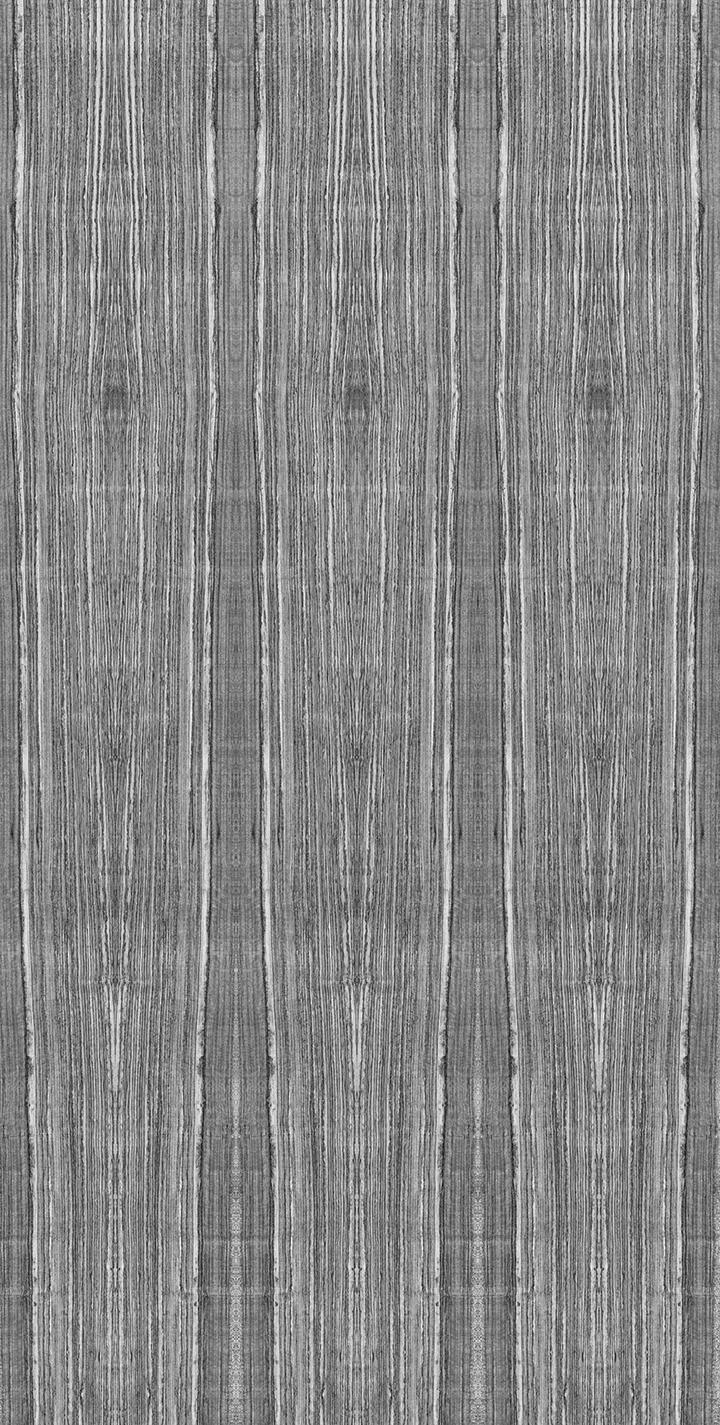

The collection spans warm cognac burls, weathered silver linears, blanched‑almond zebrawood, and more—ideal for the softly minimalist, textural direction of contemporary luxury.

4) Panel matching you can plan

Because imagery is consistent, you can specify slip or book matches with confidence—use slip for quiet, linear harmony; book for dramatic symmetry on feature walls. For whole‑room paneling, align sequencing and reveals with the Architectural Woodwork Institute (AWI) standards.

5) Fits the shop

Paper‑backed sheets lay up like other paperbacked veneers—hot press (with platen protection), cold press, or vacuum—and finish per spec. Do not re‑sand the imaged face; LithoWood is pre‑sanded before imaging.

How luxury modern interiors are using LithoWood

Architectural paneling & portals: Large‑scale slip matches (cool‑toned linears) echo stone veining and metal insets; book‑matched burls deliver a jewelry‑box moment at focal points.

Millwork & casegoods with continuity: Run the same grain and color from a concierge desk fascia to adjacent storage and wall niches, keeping perfect matches across doors and drawers—something natural veneer alone can’t always achieve at volume or on tight schedules.

Yachts, jets, and high‑touch residential: When weight, uniformity, and finish quality matter, imaged veneer on real wood substrate gives you the exact figure you want across curved partitions, closets, and cabinetry—with the tactile credibility discerning clients expect.

LithoWood vs. laminates: why it looks richer (and never “plastic”)

Most laminates (HPL/LPL) are decorative papers printed with a wood image, fused with resins, and pressed onto a substrate. They’re durable and budget‑friendly—great for utility areas—but the printed image under a wear layer can look flat compared to wood’s natural depth.

By contrast, LithoWood is real wood on the face. Grain pores, tactile texture, and wood’s subtle optical chatoyance (that soft, shifting glow) come through the finish—avoiding the plastic‑sheen effect that makes some laminates read cheap in luxury settings. In short: you keep the specification control many teams want from laminate, without sacrificing the elevated, authentic look of wood.

Need help specifying? Our team can advise on matching (slip vs. book), sequencing, substrates, and finish schedules for your exact application. Get in touch

Sources & further reading

- Herzog Veneers — LithoWood overview

- High Point Market — Herzog Veneers exhibitor listing (overview, UV‑resistant inks, paper‑backed printed veneer)

- Home News Now — “Herzog Veneers takes digital wood imaging to the next level”

- Architectural Woodwork Institute — Standards (matching & sequencing concepts)

- Composite Panel Association — What is HPL?

- Wikipedia — Decorative laminate